KVVR cable and KVVP cable difference

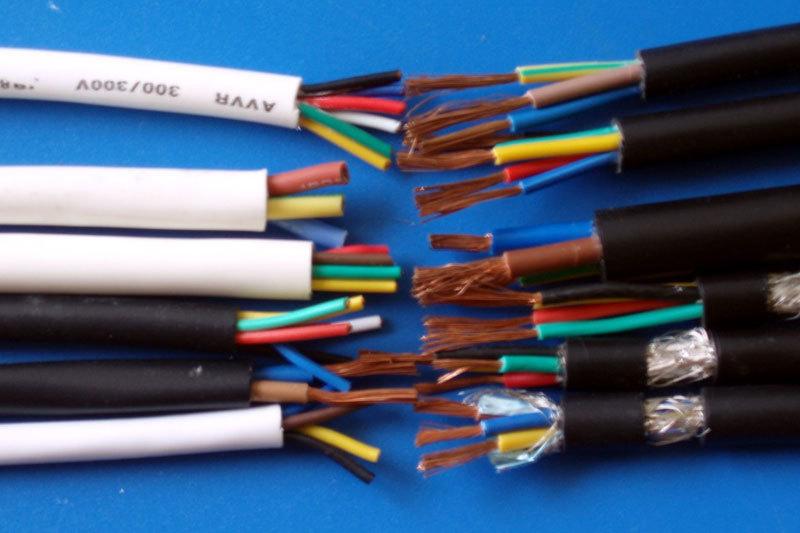

Control cables play a vital role in modern industry. They are used to transmit signals and electricity to help control the operation of various equipment and systems. Among the many control cables, kvvr and kvvp cables are two common types. Although they look similar, there are actually some important differences.

First of all, from the appearance point of view, the structure of kvvr and kvvp cables is very similar. They all consist of multiple insulation layers, wires and sheaths. However, the main difference between these two cables is the internal wire structure. Both kvvr and kvvp cables use copper conductors. Kvvr uses multi-strand copper wire conductors, and kvvp uses a single soft round copper wire as the conductor, which means that kvvp cables have better conductivity and oxidation resistance. Therefore, kvvp cables are more common in some application scenarios that require higher conductivity.

Secondly, the electrical characteristics of the two cables are also slightly different. The electrical parameters of kvvr cable are more stable, and its resistance and inductance are lower, which can provide better signal transmission quality. The kvvp cable has better anti-interference ability, which is suitable for some scenes with complex environment and vulnerable to external interference. Therefore, in industrial automation systems and mechanical equipment control systems, kvvp cables are often selected to ensure the stability and reliability of signal transmission.

In addition, the flame retardant properties of the two cables are also different. Kvvr cable usually uses polyvinyl chloride as the sheath material, its flame retardant performance is poor, easy to release toxic gases in the case of fire. The kvvp cable can be used with better flame retardant materials to provide higher safety performance. Therefore, in some of the fire safety requirements of the environment, kvvp cable is widely used.

In addition, there are some differences in the price of the two cables. Due to the difference in conductor materials and electrical properties, kvvp cables are usually more expensive than kvvr cables. Therefore, when choosing a cable, you need to consider the budget and performance requirements, and choose the most suitable model.

KVVR cable and KVVP cable are a kind of frequency conversion control cable, respectively, control flexible cable and control shielded cable. Their rated voltage is 450/750V. KVVR cables are mainly used in household appliances, electronic equipment, dashboards, automatic mechanical data signal power plugs and other occasions. They use high-quality polyvinyl chloride materials to replace RVV cables. Because of its good shielding performance, KVVP cable is suitable for power plants, power stations and other places. It should be installed indoors, cable trenches, pipelines and direct burial places that can withstand large mechanical tension.

The advantages of KVVR cables include: temperature resistance, flame retardant, cold resistance, acid and alkali resistance, anti-aging and good insulation properties.

The advantages of KVVP cables are:

1. It has good oxidation resistance and anti-ultraviolet radiation performance, and it is not easy to crack when working outdoors for a long time;

2, with good electrical performance, can withstand the impact of corona and arc;

3. Excellent mechanical properties, good chemical resistance and fuel resistance;

4, non-toxic and tasteless, low surface activity and low water absorption.

In summary, although kvvr and kvvp cables are very similar in appearance, there are certain differences in their internal wire structure, electrical characteristics, flame retardant performance and price. When choosing a control cable, it is necessary to decide which type of cable to use according to the specific application requirements to ensure the stability, reliability and safety of the system.

Key words:

Share